| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Custom LOGO

Model Number : HW-585

Certification : ISO9001

Place of Origin : China

MOQ : 1set

Price : 2000-10000USD

Payment Terms : T/T , Paypal

Supply Ability : 40sets/month

Delivery Time : 25-40days

Packaging Details : wood carton, as customer requested

Name : Plastic injection molds

Mold Design software : PRO/E, Solidwork, UG, Autocad, etc

Mold Base : LKM,HASCO,DME,etc.

Plastic Material : BS+PC,PBT,PBT+GF30,PPS,etc

Mold Life : >300 Thousand Shots

Surface finish : Texture, smooth, glossy or mirror polished, etc

Mould size : Any size as per customer's requirement

Experiences : More than 12 years experience

lead time : 20-30 working days after receiving deposit

OEM S45C Injection Mold Maker 500000 Time Plastic Injection Molding

Mold Maker OEM S45c Plastic Injection Mold With 500000 Mold Life Time

Custom Single/Multi Cavity Injection Moulding for Automotive Glove Box

| PLASTIC INJECTION PART BASIC INFORMATION | |

| Product Name | High Precision Mould |

| Product Material | ABS, PA, PA66+30GF, PBT, PC, POM, PP, PE, MA,PVC,TPE,TPU etc |

| Surface Requirement | Smooth, Polishing, Painting, SandBlasting, Electroplate, Silk-screen, Laser Etching, Anodizing,Brushing |

| Plastic Part Resin | Thermoplastic/Thermosetting |

| Tolerance Request | UP to (±0.005mm) |

| Lifetime | >300 Thousand Times |

| Part Size Range | 5-1000mm,or customized |

| Multi Injection | Single/Double/multi color |

| Design Software | Pro/E,UG,Catia,Woodwork,Moldflow,AutoCad |

| Quality Assurance | Design Control, Steel Hardness Inspection Report, Steel Dimension Control Report, Mold Core and Cavity Dimension Inspection Report |

| PLASTIC INJECTION MOULD BASIC DESCRIPTION | |

| Injection System | Hot /Cold Runner |

| Inserts(cavity and core) | H13, 1.2344, 1.2738, 1.2083, 1.2311, NAK80 or the material you required. |

| Mold Cavity | 1*1,1+1,1*2,1+1+1,etc |

| Gate type | Side gate,Sub gate,Pin point gate,Edge gate etc |

| Ejector System | Stripper plate,Lifter,Push bar,Ejection pin etc |

| Steel Standard | FINKL,Assab,DAIDO,LKM,Buderus |

| Cooling | Baffles/Sprin Piple/3D printing water line |

| Lead time of first samples | Around 4~7weeks |

| Standard Parts/Cylinders | DME/HASCO/PROGRESSIVE/MISUMI/Parker/HP/Merkle |

| Design Capability | DFM,Mould flow analysis,Product optimization, Full 2D & 3D mould design,Reverse engineering,Collaborative design with customer's idea |

| Documents / Reports Provided | Fully drawing,Weekly Processing Report, Steel Dimension report, Processing Report,Sample Dimension Report. |

| HOWE can make the automotive parts as following | |

| Automotive Front Bumper | Automotive Seat Part |

| Automotive Grilles | Automotive Lamp |

| Automotive Bracket Fog | Automotive Splash Shield |

| Automotive Fender | Automotive Air Outlet |

| Automotive Door Panels | Automotive Glove Box |

| Automotive Mirror Shell | Automotive Radiator Tank |

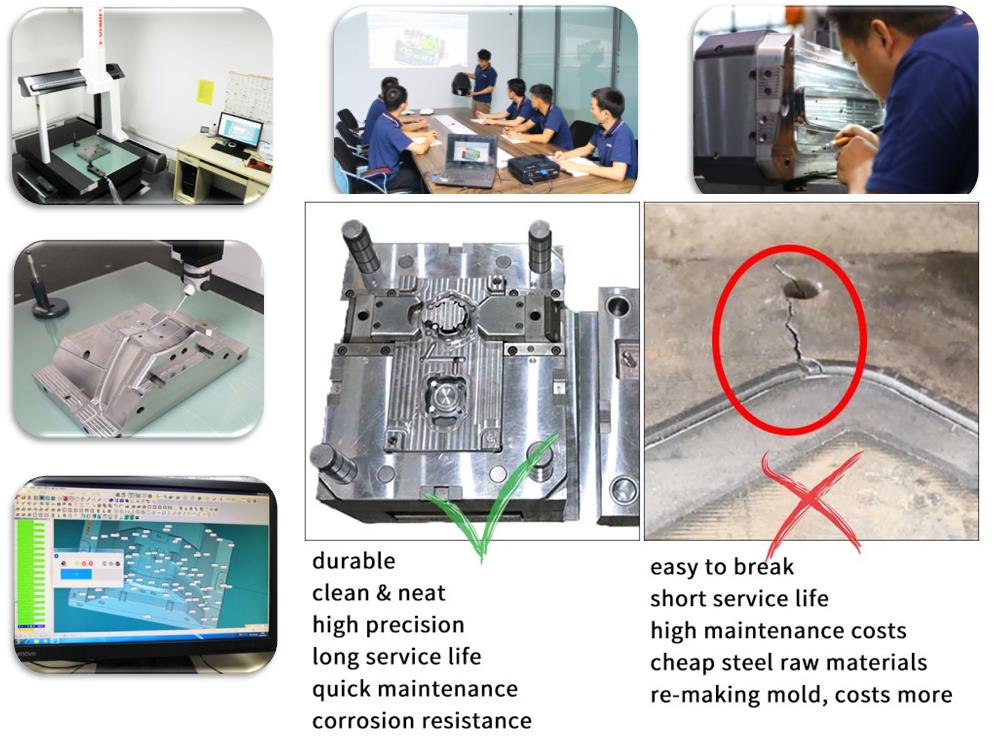

Howe Mould Quality Control

1. Mould Material Q/C

a) mould steel checking (hardness,flaw detection)

b) mould spare parts checking (hardness,size)

2.Mould Making Process Q/C

a) design checking ( part design,mould design,mould engineering drawing)

b) mould size checking (according to drawing)

c) mould testing (check mould working,sample)

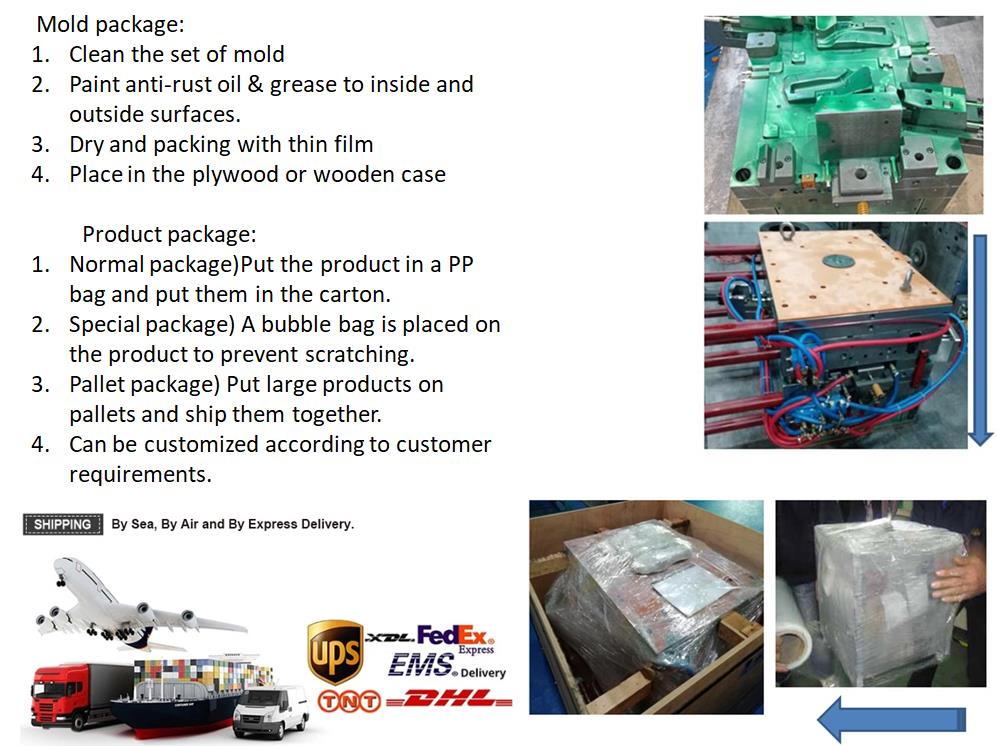

Package and Shipping

FAQ About plastic injection moulding parts

Q1: How many injection plastic mouldings machines do you have?

A1: We have 40 sets of plastic Injection Mouldings machines.

Q2: what are the minimum & maximum unit weight and size your machines can produce?

A2: Our machines produce unit parts from 1 gram to 6000 grams of weight.

Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Q3: What kind of plastic materials you usually use?

A3: We are specialized in producing plastic products with the following materials:

PP, ABS,PC,POM,PA,HDPE,HIPE,PS,AS,PBT,PET,PMMA,PVC and so on.

Q4: How do you pack the plastic molded parts?

A4: We pack the plastic molded parts by thick-wall cartons.

If the finished surface of plastic molded parts requires safe protection to avoid scratches, we will use a bubble plastic bag to pack the parts.

FAQ About Worldwide Delivery

Q5: Can you deliver the plastic moulds or plastic products to our factory?

A5: Yes, We have cooperated with many international logistics companies for years.

And we have full experience to manage the delivery directly to the client's factory or appointed warehouse.

|

|

OEM S45C Injection Mold Maker 500000 Time Plastic Injection Molding Images |